EDM consumables

Achieve maximum return from every wire EDM machine.

Coolant management

Consistent concentration for accurate production.

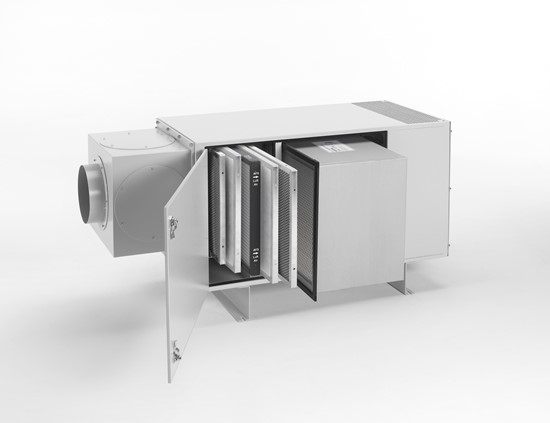

Mist extraction

Optimal air quality in every production environment.

Optimize processes.

Increase quality.

Produce more efficiently.

MP Solutions brings together the technical expertise of Petroline and Sommen-EDM in one integrated approach for the manufacturing industry. From this combination, we support production companies in achieving stable, safe and future-proof processes. Our focus is on the conditions that determine the quality of every CNC and EDM process: clean air, consistent coolant values and a reliable spark process. This creates a predictable production environment in which accuracy and continuity remain assured

The benefits you notice immediately in your production process

When critical steps in your CNC process are set up correctly, this is immediately reflected in capacity, accuracy and predictability. A stable machine fleet delivers consistent quality, fewer disruptions and a production environment that is prepared for the technical requirements of the years ahead. This allows you to get more out of every operation, without adding extra strain on your organization.

We understand your industry

Every sector has specific requirements when it comes to precision, safety and continuity. Our systems are closely aligned with your machine fleet, ensuring stable processes, predictable maintenance and consistent product quality.

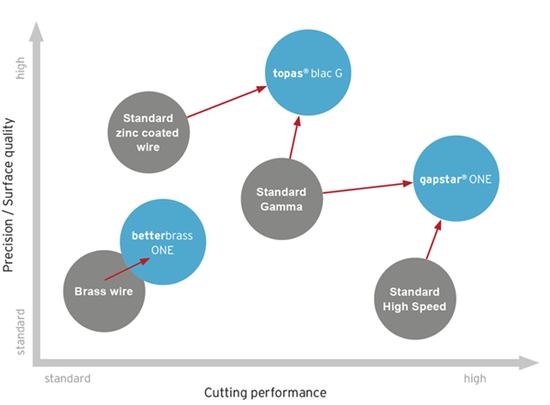

EDM wire highlights

To achieve maximum return from a wire EDM machine, these wire types offer the optimal combination of reliability, cutting speed, contour accuracy and surface quality.

gapstar® ONE

This newly developed TRIMPAC coating delivers cutting speed increases of up to 40%.

topas® blac G

The latest wire developed for high precision and superior surface quality.

betterbrass ONE

A brass wire with a new alloy delivers up to 10% higher cutting speed and a more stable machining process.

What our customers say

Clean air and improved working conditions

Our mist extraction systems provide effective and reliable filtration of oil and emulsion mist released during metalworking processes. The systems combine multi-stage filtration with a long-life separator developed by AFS.

The long-life separator removes the majority of oil and emulsion particles at an early stage. This keeps filter loading low and significantly extends filter service life. The HEPA filter then provides fine post-filtration, returning clean and safe air to the working environment.

Our systems are distinguished by high filtration performance, low maintenance requirements and long service intervals. They are suitable for both air recirculation and exhaust to the outside, and can be integrated seamlessly with heat recovery systems. This improves indoor air quality while also contributing to energy savings and long-term sustainability.

Partner to European manufacturing companies

Since 1989

As a manufacturing company, you need to be able to rely on stable processes and dependable support. That is why companies in the Netherlands, Belgium and Luxembourg rely on MP Solutions for EDM consumables, mist extraction and filtration systems. The Petrofill refill system is part of our own product line and is supplied directly within the Benelux. In Germany, Austria, Switzerland, the Czech Republic and Norway, specialised dealers provide the same level of support and supply reliability.

Plan your personal

consultation

Plan your personal consultation and discover how automated coolant management, mist extraction and EDM applications support greater process continuity and lower operating costs.

.png?width=550)

.png?width=550)

.png?width=550)

.png?width=550)

.jpg?width=550)