Why choose

central mist extraction?

High quality standards

Meet requirements for air quality and safety in the production environment.

24/7 production

Constant extraction capacity, even during long or unattended production.

Working conditions

Prevent exposure to harmful fumes.

Sustainability

Reduce energy consumption and extend machine service life.

Effective mist extraction.

A cleaner workplace.

Our mist extraction systems use high-grade filtration, including HEPA technology combined with the Long-Life Separator developed by AFS. This configuration significantly extends HEPA filter service life and keeps airflow stable over time. Oil and emulsion mist are effectively captured, ensuring a consistent indoor climate for both personnel and processes.

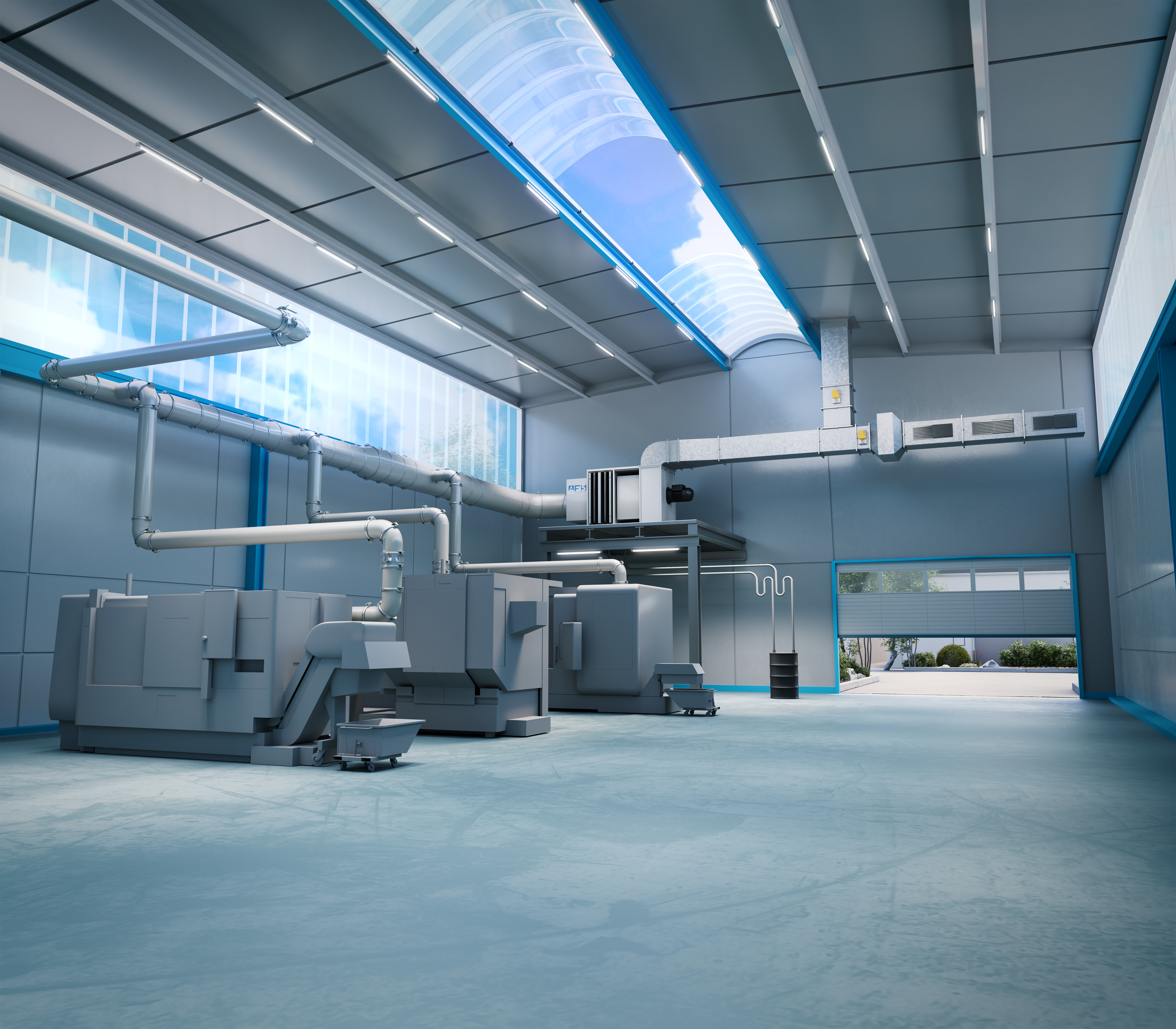

Central mist extraction

Central mist extraction from MP Solutions delivers maximum efficiency in production environments where multiple machines operate simultaneously. By combining high capacity with controlled airflow, these systems create a stable, clean working environment in which employees can work safely and comfortably. Contaminated air, odour and humidity are either exhausted or recirculated, resulting in a measurable improvement in air quality.

- Less odour, less residue, less contamination

- Improved working conditions

- Energy recovery and lower operating costs through heat exchangers

- Reduced maintenance and lower energy consumption through a central unit

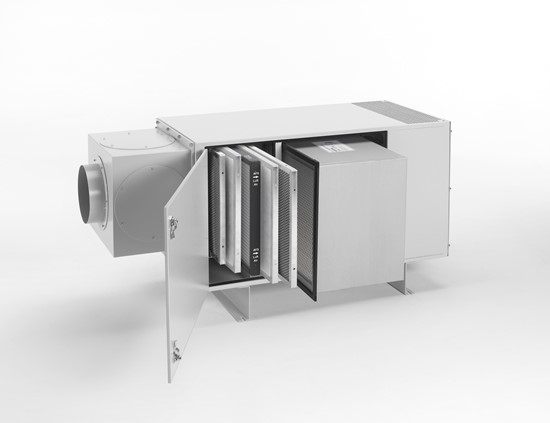

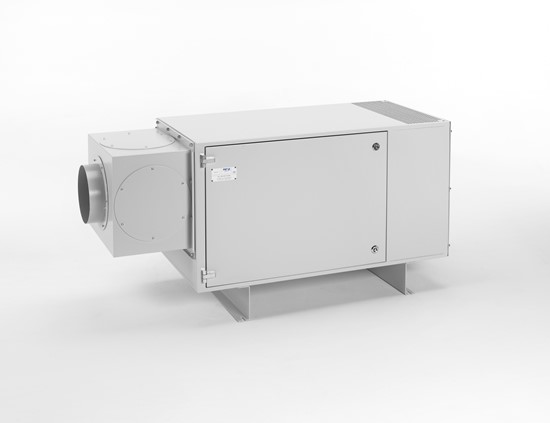

Single units

For smaller machines and specific operations, we supply compact mist extraction units with high filtration efficiency. These units remove oil and emulsion particles directly at the source, keeping the production process clean and stable. They are designed for easy maintenance, long service life and reliable continuous operation. Thanks to their compact design, they can be installed directly on or next to the machine without modification to existing installations.

From process analysis to an integrated approach

Elke productieomgeving is uniek. Daarom leveren wij geen standaardoplossingen, maar systemen die volledig zijn afgestemd op jouw proces. Onze specialisten analyseren de huidige situatie, adviseren gericht en realiseren een integratie die direct rendement oplevert.

- Analyse van jouw proces en doelstellingen

- Advies en configuratie van de juiste technologie

- Installatie, testfase en nazorg voor optimale prestaties

Discover the value of optimal air quality

Explore all technical details and practical applications of our mist extraction systems.

What our customers say

Structured maintenance for a stable extraction process

The performance of an extraction system is directly linked to filter condition. As filters become saturated, extraction capacity decreases and air quality becomes less stable. On average, cleaning or replacement is required after three months to maintain consistent air quality. We determine the correct maintenance interval per machine and take full responsibility for maintenance. You also receive an annual overview of all scheduled service visits, providing complete clarity and predictability.

Frequently asked questions

The choice depends on mist load, machine power, type of operation, filtration rate and thermal load. For light to moderate load, an individual unit is usually sufficient. For high load or multiple machines, a central system is often more efficient. A technical assessment determines the required air volumes, pressure values and filter efficiency.

Mechanical separation removes larger particles but offers limited control over fine aerosols.

HEPA filtration removes ultra-fine particles according to a standardised filter class.

LLS technology (Long-Life Separator) from AFS separates medium and large mist particles before they reach the main filter.

The combination of LLS and HEPA results in long service life, consistent performance and low pressure drop across the entire operating range

Individual units

- suitable for machines with varying load

- fast installation with minimal ducting

- lower investment per machine

Central systems

- more efficient for multiple machines

- lower energy demand per m³ of air

- possibility of heat recovery

- central monitoring and filter management

The best choice depends on load profile, number of machines and future growth. We are happy to advise you.

The required capacity is determined by machine volume, type of operation, spindle speed, thermal load, amount of coolant and the degree of machine enclosure. An incorrectly sized system results in insufficient extraction or excessive pressure drop. We support you in selecting the correct extraction units for your production environment.

Yes, provided the ducting is correctly designed and automatic volume control is applied per connection. Without proper balancing, one machine can dominate the system, causing uneven performance across the line.

Discover your productivity potential

Meet our experts and discover how mist extraction makes your production environment healthier and more energy-efficient.

.png?width=550)

.jpg?width=550)