Why choose EDM consumables

from MP Solutions?

German-quality wire

Consistent wire quality with predictable performance for stable and accurate machining.

Expert advice

Support in selecting the right wire for precision, surface quality and high cutting speeds.

Process reliability with every cut

Consistent results during long production runs.

Achieve maximum return from every wire EDM machine

MP Solutions supports you in achieving maximum return from every wire EDM machine. We supply exclusively German-manufactured, high-grade products developed for consistent performance and maximum reliability. Our specialists work closely with you to optimise your wire EDM process, reducing cycle time and operating costs while maintaining full process control. In addition, our systems deliver the highest levels of precision and surface quality, even for the most demanding applications.

&cropxunits=600&cropyunits=164)

EDM wire highlights

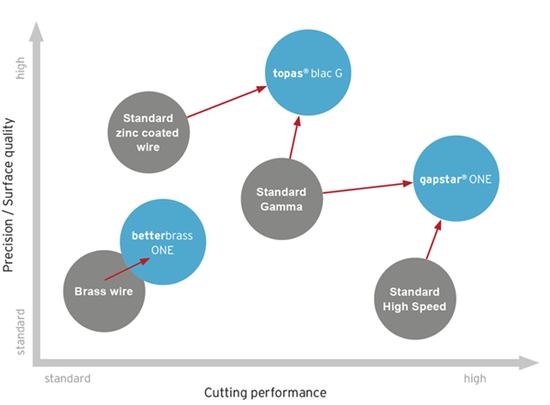

To achieve maximum return from a wire EDM machine, these wire types provide the optimal balance of reliability, cutting speed, contour accuracy and surface quality.

gapstar® ONE

This newly developed TRIMPAC coating delivers cutting speed increases of up to 40%.

topas® blac G

The latest wire developed for maximum precision and superior surface quality.

betterbrass ONE

The latest brass wire, featuring a new alloy, delivers up to 10% higher cutting speed and a more stable machining process.

From process analysis to an integrated approach

Every production environment is unique.

That is why we do not deliver standard systems, but EDM consumables fully aligned with your specific process. Our specialists analyse the current situation, provide targeted advice and implement an integration that delivers measurable results.

- Analysis of your process and objectives

- Advice and configuration of the appropriate technology

- Installation, testing phase and aftercare for optimal performance

Download

the brochure

Discover the contribution of high-quality EDM consumables.

Read more about the technical features and practical application within modern EDM processes.

What our customers say

Our expertise

MP Solutions supports manufacturing companies in optimising their wire EDM processes. With in-depth knowledge of EDM technology, we advise on wire selection, filtration and related consumables that keep the spark process clean and maintain process quality. This ensures every operation remains predictable, accurate and repeatable, even for complex contours and extended production runs.

Veelgestelde vragen

Even minor variations in temperature or coolant conditions directly affect dimensional accuracy. Stable process conditions are required to maintain reproducible tolerances across all machining operations.

Discover your EDM potential

Meet our specialists and gain insight into which EDM consumables make your process more accurate and predictable.

.png?width=550)

.png?width=550)

.png?width=550)

.png?width=550)

.jpg?width=550)