Why choose belt filters for

CNC machines?

Extended coolant service life

Continuous belt filtration keeps emulsion and oil stable for longer periods, significantly extending coolant service life.

Reduced machine wear

Effective filtration of chips and fine particles prevents contamination and corrosion, reducing mechanical load and wear on CNC machines.

Predictable process quality

Clean and stable coolant supports accurate machining operations and prevents unplanned downtime during CNC machining.

Lower consumption of consumables

Thanks to the efficient filter design, filter media consumption is reduced and maintenance intervals are extended.

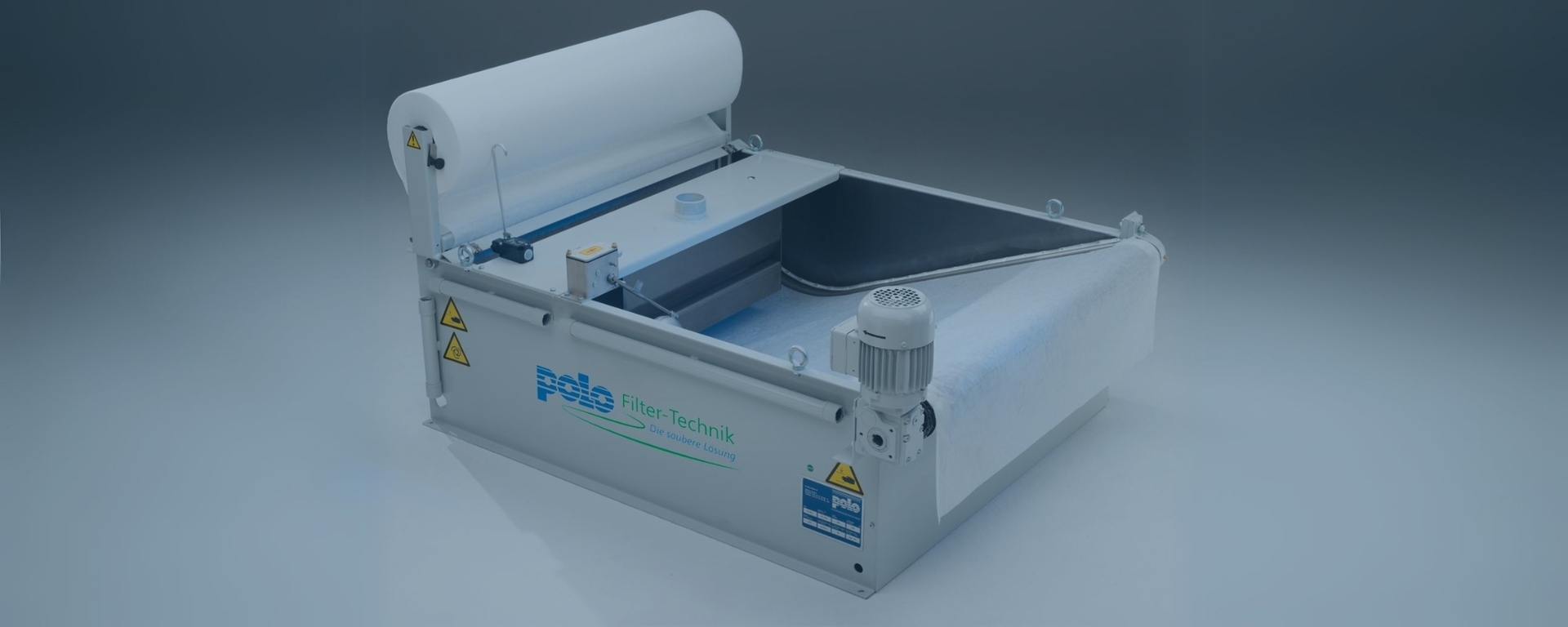

Belt filtration down to 10 microns

With our belt filters for CNC machines, coolant is continuously filtered down to 10 microns. The system removes fine contaminants from the coolant, keeping viscosity and quality within the correct process parameters.

The result is a stable and reproducible machining process, reduced wear on machine components and extended service life of both coolant and tooling.

Coolant quality that supports the machining process

Our belt filters for CNC machines are designed to actively support coolant quality and integrate seamlessly with both individual CNC machines and larger production environments. Thanks to their flexible and modular design, the systems can be easily integrated into existing installations and expanded as process requirements change.

- Suitable for a wide range of CNC machining machines

- Modular expansion with additional filtration stages for higher precision

- Applicable in both central and decentralised filtration concepts

From process analysis to an integrated solution

Every production environment is unique. That is why we do not deliver standard systems, but solutions fully aligned with your process. Our specialists analyse the current situation, provide targeted advice and implement an integration that delivers measurable results.

- Analysis of your process and objectives

- Advice and configuration of the appropriate technology

- Installation, testing phase and aftercare for optimal performance

Download

the brochure

Discover what our oil filtration systems deliver

View all technical details and practical applications of our oil filtration systems.

Our expertise

MP Solutions supports manufacturing companies in optimising their coolant management. With many years of experience and in-depth knowledge of the manufacturing industry, we develop systems that increase continuity, reduce downtime and safeguard process quality. Petrofill Brix-Control™ plays a central role as a proven technology for efficient and sustainable production management.

Frequently asked questions

Contamination in cutting oil or coolant causes variation in dimensional accuracy and increases load on machine components. Continuous fine filtration keeps oil condition stable, making the machining process predictable and reproducible. MP Solutions advises which filtration stages match your accuracy and process requirements.

A belt filter removes fine solid particles, wear debris and other contaminants released during machining. This keeps oil viscosity stable and prevents blockages in lines and cooling channels, supporting a clean coolant circuit and consistent process quality.

Belt filters have a long service life and require relatively little maintenance. Filter replacement is periodic and depends on process load and contamination levels. Clean oil or emulsion reduces machine maintenance, as wear and blockages are limited.

Yes. Belt filters can be applied to individual CNC machines or integrated into a central filtration system. Thanks to the modular design, additional filtration stages can be added when higher precision or finer filtration is required.

MP Solutions analyses factors such as oil contamination level, machining tolerances and the required level of process stability. Based on this analysis, we advise the appropriate filter configuration, filtration grade and system setup for your production environment and machine fleet.

Discover your productivity potential

Meet our experts and discover the benefits of effective filtration for your production environment.