Industries

Our solutions

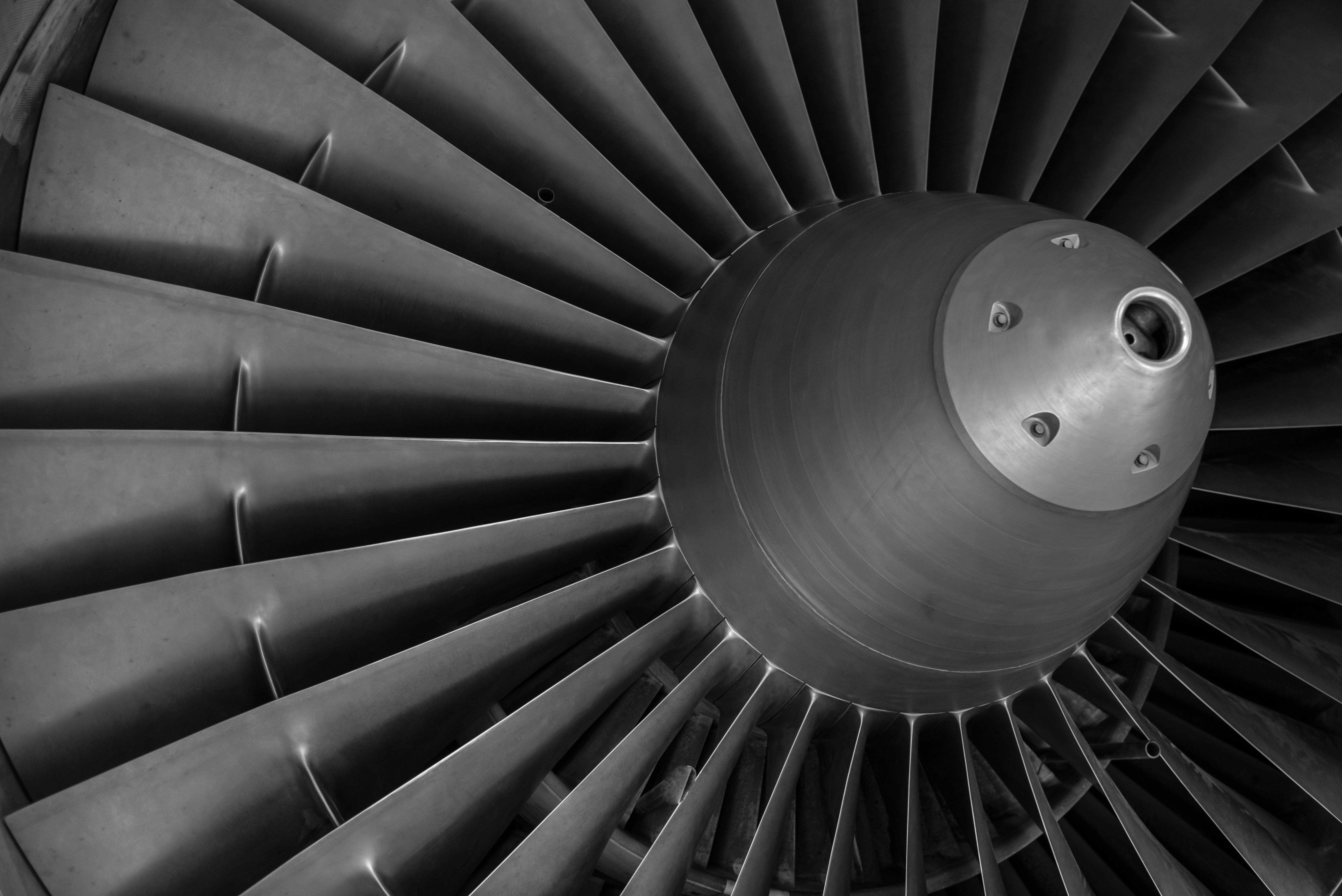

for aviation manufacturing

EDM consumables

Achieve maximum return from every wire EDM machine.

Coolant management

Consistent concentration for accurate production.

Mist extraction

Optimal air quality in every production environment.

We understand

your industry

Even minor variations in temperature or coolant conditions directly affect dimensional accuracy. Stable process conditions are required to maintain reproducible tolerances across all machining operations.

Every step within the production process must be traceable. Unstable process conditions interfere with documentation, monitoring and quality assurance. Consistency is essential to meet aviation standards and certification requirements.

Materials such as titanium and Inconel respond immediately to changes in concentration and temperature. Precise regulation prevents variation in surface quality and reduces the need for rework or secondary operations.

Temperature fluctuations within the production hall influence material behaviour, thermal expansion and measurement accuracy. A stable environment is required to keep tolerances predictable and controllable.

Applications within aviation manufacturing

Aviation components are produced under strictly controlled conditions. Our systems support machining processes where accuracy, material integrity and reproducible dimensional control are critical. They are applied in:

- precision components for actuation systems and valves

- components made from high-temperature materials

- fine mechanical tolerances in turning, milling and grinding operations

- series production with controlled and traceable process conditions

- EDM machining for critical geometries

Proud of our collaborations

within the aviation industry

Process analysis

We assess the process conditions within your production environment and determine which systems are required to achieve reproducible and controlled machining results

Process reliability through structured maintenance

Aviation manufacturing requires continuous process control. We provide maintenance that keeps machining conditions stable, with fixed service moments each year and inspection of filters and critical components. During each service visit, filters are cleaned or replaced and system conditions and air quality are assessed. You receive a clear report with system status and planning. Deviations are addressed immediately to prevent unplanned downtime.

Frequently asked questions

Stable coolant quality, clean oil and consistent air quality prevent temperature variation and contamination. This keeps dimensional accuracy reproducible, even for machining operations with micron-level tolerances. MP Solutions advises which system configuration best fits your specific application.

Yes. Our systems support processes where traceability and reproducible conditions are required. Parameters such as Brix value, pH and temperature can be continuously monitored and recorded, supporting quality documentation and process control.

Machining high-temperature materials releases fine oil and emulsion mist. Without effective filtration, this affects both air quality and temperature stability within the production hall. A stable climate supports measurement accuracy and reduces the risk of deviations.

During fixed service intervals, filters are cleaned or replaced and coolant condition, oil quality and air filtration performance are assessed. Deviations are addressed immediately. After each service visit, you receive a report with system status and recommendations, keeping process conditions controlled and predictable.

We analyse your machining processes, materials, tolerances and quality requirements. Based on this analysis, we advise systems for coolant management, mist extraction or oil filtration that meet both accuracy and control demands within aviation manufacturing.

Yes. MP Solutions analyses the current situation and advises a configuration that fits within existing workflows, machine layouts and quality standards. Integration is carried out in phases, allowing production to continue without interruption.

Discover your productivity potential

Our specialists are ready to support you in creating a stable production environment, reliable filtration and accurate machining processes within the aviation industry.